Module 1

Competences and resources necessary for the transformation to Industry 5.0 at the local level

Introduction

Learning objectives

Micro-lessons

Lesson 1

Introductory thoughts

Lesson 2

The industrial revolution - Industry 1.0

Lesson 3

Electrification and mass production - Industry 2.0

Lesson 4

Introduction of electricity and assembly line work - the example of Henry Ford

Lesson 5

Automation and computerisation - Industry 3.0

Lesson 6

Networking and cyber-physical systems - Industry 4.0

Lesson 7

The "smart" factory - the example of "Factory 56" from Mercedes-Benz

Lesson 8

Industry 5.0 - Definition

Lesson 9

The most important differences between Industry 4.0 and Industry 5.0

Lesson 10

Areas of interaction between man and machine

Lesson 11

Changing job profiles - The Emsi Burning Glass Study 2022

Lesson 12

A changed job profile - the example of the marketing specialist

Lesson 13

New resources and expertise for Industry 5.0

Lesson 14

Future of Jobs Report 2023 - Skills of the future

Lesson 15

Industries and skills development - A study by the WEF Future of Jobs Report 2023

Lesson 16

Discrepancy between training provision and skills requirements

Lesson 17

Training methods

Lesson 18

Sustainability in Industry 5.0 - Definition of sustainability

Lesson 19

Principles and goals of sustainability - Agenda 2030

Lesson 20

Importance of sustainability for Industry 5.0

Lesson 21

Sustainability through intelligent production - the Siemens Amberg electronics factory as an example

Lesson 22

In-depth study of Industry 5.0 and sustainability - Siemens factory video

Lesson 23

Industry 5.0 - advantages for people

Lesson 24

Criticism of the term Industry 5.0

Lesson 25

Challenges and hurdles in the introduction of Industry 5.0

Lesson 26

Ethical considerations

Lesson 27

Websites on ethics and AI

Lesson 28

Risks associated with the use of AI in Industry 5.0

Lesson 29

Industry 5.0?

Lesson 30

Summary

Module 1 - Practical exercises

Good Practices

Good practice 1

Bosch - Example of Electromobility

Good practice 2

Festo - Example of Collaborative Robotics

Good practice 3

Schneider Electric – Example of IoT

Good practice 4

Asea Brown Boveri - Example of Collaborative Robotics

Industry 5.0 is the next step in industrial development, where the focus is not just on technology and efficiency, but on combining human creativity and skills with advanced technologies. Put simply, it aims to put people back at the centre of industrial processes by ensuring that automation and intelligent systems work alongside the unique skills of the human workforce.

This module introduces people working in SMEs, managers in general and VET teachers in particular to the newness of Industry 5.0 and how a fruitful balance between man and machine can help create better and more personalised products while ensuring that workers undertake meaningful and fulfilling tasks.

At the end of this module you will be able to

- to fully understand and explain the concept of Industry 5.0 in contrast to Industry 4.0,

- recognise the changes in job profiles and in the skills required to perform the job,

- explain the role of environmental, social and economic sustainability in Industry 5.0,

- identify and critically apply ethical issues in connection with the introduction of Industry 5.0.

Lesson 1 - Introductory thoughts

The concept of Industry 5.0 has been circulating among experts for some time. In 2021, the European Commission took up the term and developed it into a concept paper, which it itself described as a "vision" (p. 3), in order to define and shape the direction of Industry 5.0. The paper was created because the European Union sees itself as having a responsibility to make a forward-looking contribution to the changing requirements of industry and society.

Social and economic conditions in Europe have changed significantly over the last decade. It is therefore increasingly important, not least due to the global economic pressure on the European economy, to support European industry and its independence and progress in order to drive forward Europe's competitiveness. This is all the more of a challenge as many European countries are already experiencing a shortage of skilled labour and the "baby boomer" generation will be retiring in the coming years. The European Commission sees potential here for Industry 5.0, namely that Industry 5.0 could provide support so that the associated digitalisation could change jobs in such a way that the labour shortage can be counteracted without jeopardising existing jobs. The EU therefore sees itself called upon to assume social responsibility, not only for the labour force itself but also for social values such as equality, inclusion and diversity, as well as for sustainability and ecology in line with the "Green Deal". This vision of Industry 5.0 is followed below.

Source: https://pixabay.com/de/photos/wald-hoffnung-strahlende-zen-396025/

Lesson 2 - The industrial revolution - Industry 1.0

The causes of the Industrial Revolution are not fully understood. It is assumed that various favourable factors must have interacted. Characteristic of the Industrial Revolution was that it involved a "complex process of transforming the pre-industrial economy, which was characterised by low production and a tendency towards stagnation, into an industrial economy with rising production, a relatively high standard of living and sustained growth". (Niemann, p. 67). In the process, the nature of gainful employment changed from agriculture to entrepreneurship with specialised jobs and labour supported by machinery.

The Industrial Revolution began in Great Britain and spread from there to other countries. The cloth industry with its mechanical looms can be cited as an example. It seems that cloth production was the economic sector in which the technological revolution first manifested itself. The invention and introduction of first the "flying shuttle" and then the water or steam-powered loom meant that human labour was replaced by mechanical labour, making it possible to produce and process faster, better, more and at lower cost.

Source: https://pixabay.com/de/photos/webstuhl-seide-garnrolle-weben-361631/

Lesson 3 - Electrification and mass production - Industry 2.0

Industry 2.0 was characterised by the use of electricity as a driving force, as well as the use of motors and the switch to assembly line work. With electricity as a new energy source, production became more flexible and less dependent on water and steam. Factories were no longer tied to specific locations (near water, coal areas) and electricity allowed machines to operate more reliably and consistently.

Electrification also improved many aspects that were secondarily linked to production in the factory. For example, communication technologies such as the telephone and telegram improved the speed of information transfer. The infrastructure also expanded, as electricity and the use of engines also made steam locomotives and steamships even better and faster means of transport. As a result, production processes became more efficient overall and were no longer limited to a small geographical area. This led to an increase in productivity and a further reduction in costs, which improved the competitiveness of companies. The first steps towards globalisation had been taken.

Source: https://pixabay.com/de/vectors/elektrizit%C3%A4t-pylon-silhouette-5004309/

Lesson 4 - Introduction of electricity and assembly line work - the example of Henry Ford

With the introduction of the assembly line in his automobile factories, Henry Ford revolutionised production processes in the manufacturing industry. Ford realised that by breaking down the production process into individual, repeatable steps and arranging the workstations along an assembly line, production time could be significantly reduced. As each employee was only responsible for one specific task, a high level of efficiency and standardisation could be achieved.

The best-known example of the first assembly line production is the Model T, also affectionately known as the "Tin Lizzie". By using the assembly line, Ford was able to reduce the production time of a vehicle from 12.5 hours to 1.5 hours. This led to a massive reduction in costs, making the car accessible to the masses. The Model T became a symbol of American progress and characterised the mobility of an entire generation.

Source: https://pixabay.com/de/photos/oldtimer-wagen-fahrzeug-ford-7187757/

Lesson 5 - Automation and computerisation - Industry 3.0

Industry 3.0, or the "third industrial revolution", was characterised by the increasing automation and computerisation of production processes. It began in the 1960s. In contrast to the previous industrial revolutions, which focussed on the expansion of mechanical processes and electrical energy, electronic control systems and computer technology were central to the Industry 3.0 phase. Industry 3.0 thus laid the foundation for today's digital transformation.

In this phase, automation means that machines and technologies are introduced that carry out and monitor production processes independently. This means that they take over tasks that were previously carried out by people. The use of machines and technologies makes production more trouble-free and efficient. New in this period were programmable logic controllers (PLCs) and robots, which were characterised by precision and the ability to perform repeatable tasks.

Computerisation refers to the integration of computers into the production process, which forms the basis for automation. In particular, CAD/CAM systems (computer-aided design/computer-aided manufacturing), which enable the computer-aided completion of products and have led to the development of computer-integrated manufacturing (CIM) systems.

Industry 3.0 thus enabled more flexible and efficient production, in which human labour was increasingly supported and / or replaced by machines and computers.

Lesson 6 - Networking and cyber-physical systems - Industry 4.0

Ovens or heaters with thermostats that can be switched on and controlled remotely or coffee machines that always provide coffee at the same time every morning are devices that are categorised under the term Internet of Things (IoT). These devices are part of Industry 4.0.

How do you recognise a "smart" device?

- Devices of this type are connected with the internet and can be controlled remotely via an app on a smartphone or a browser.

- Such devices have integrated sensors that detect and analyse data (e.g. temperature).

- Over time, some devices of this type can adapt their functions independently on the basis of the stored data, i.e. they are capable of learning.

More in-depth and helpful information on the Internet of Things can also be found here: https://www.infineon.com/cms/de/discoveries/internet-der-dinge-basics/

Lesson 7 - The "smart" factory - the example of "Factory 56" from Mercedes-Benz

One example of a smart factory is Mercedes-Benz's "Factory 56" in Sindelfingen, Germany. A clear explanation can be read on the Mercedes-Benz website: "Machines and systems are networked with each other. Selected assembly systems and conveyor technology are "Internet of Things"-capable. The basis for this is a high-performance WLAN and mobile phone network. The use of the high-performance 5G mobile network in assembly is to be tested for the first time in pilot applications. The assembly hall will be completely paperless. The employees work with monitors and personal digital assistants (PDAs). To supply the assembly stations, shopping baskets are used across the board, which are loaded with the required materials in a so-called pick zone with the help of intelligent picking systems. A total of 300 automated guided vehicles are in use. The resulting data is collected and analysed using big data technology. These findings are used to improve existing production processes and, for example, to prevent system malfunctions using predictive maintenance. This leads to longer operating utilisation times and improves the level of maturity." ( https://group.mercedes-benz.com/innovation/produktion/factory-56.html )

Source: https://pixabay.com/de/photos/stern-fahrzeug-pkw-mercedes-auto-1609674/

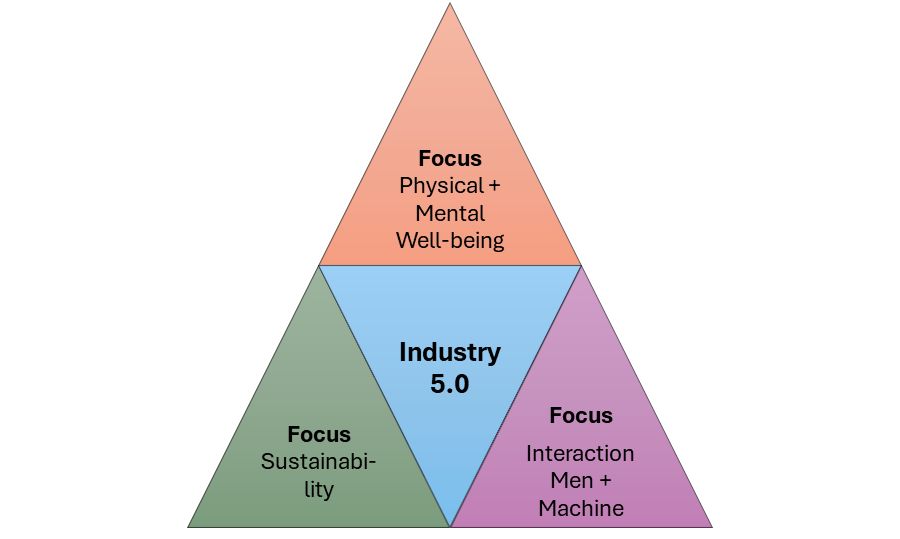

Lesson 8 - Industry 5.0 - Definition

Industry 5.0 takes into account the ability of industry to achieve societal goals beyond job creation and growth by ensuring that production respects the limits of our planet and places the well-being of workers at the centre of the production process. (EU, P. 14)

Industry 5.0 focuses on the interaction between technology, people and the environment so that economic growth is in line with sustainability goals. Thanks to the integration and utilisation of automated, digital and smart systems, key aspects of Industry 5.0 are primarily social and ecological aspects such as the environment, sustainability and the physical and mental well-being of employees.

Table 1: Priority areas of Industry 5.0

Lesson 9 - The most important differences between Industry 4.0 and Industry 5.0

The following overview compares the most significant differences between Industry 4.0 and Industry 5.0. The main differences lie in the economic approaches, the different use of technologies and the different relationship between man and machine as well as the new focus on the environment and sustainability.

Industry 4.0 |

Industry 5.0 |

Increasing efficiency through digital Connectivity and artificial intelligence |

Use of digitalisation and artificial intelligence to combine competitiveness and sustainability |

The focus is on the development of cyber-physical systems. |

Supporting employees through the use of digital devices and promoting a human-centred approach to technology. |

Optimisation of business models within the existing economic dynamics - focus on cost minimisation and profit maximisation. |

Focus on the impact of alternative forms of (technological) governance on sustainability and resilience. |

No focus on system change and detaching the consumption of resources and materials from negative environmental, climate and social impacts. |

Extending corporate responsibility to the entire value chain. Creating alternatives for the environmentally friendly use of technologies. |

Table 2: Differences between Industry 4.0 and Industry 5.0

A more detailed presentation of the table can be found in this study: European Commission, Industry 5.0: A Transformative Vision for Europe ESIR Policy Brief No. 3, Luxembourg: Publications Office of the European Union, 2022.

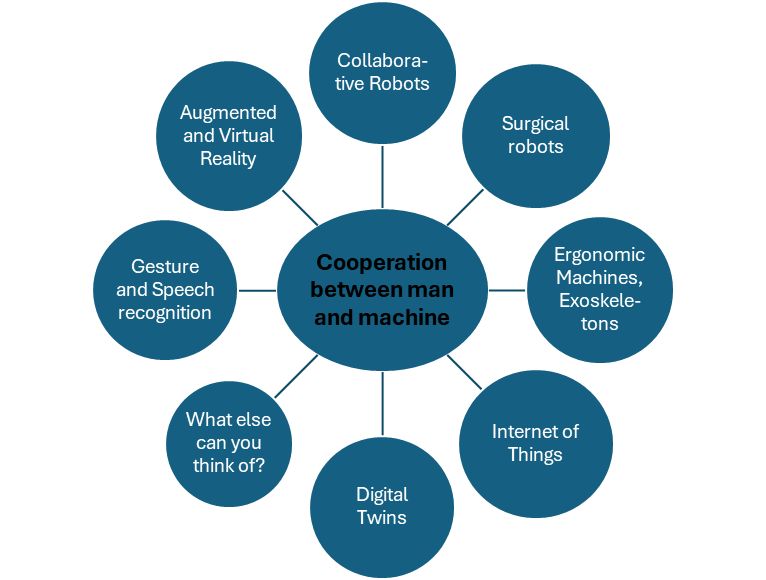

Lesson 10 - Areas of interaction between man and machine

The following illustration supports the visualisation of the cooperation between man and machine.

Table 3: Areas of human-machine interaction, adapted from Birgit Vogel-Heuser Klaus Bengle, "Von Industrie 4.0 zu Industrie 5.0 - Idee, Konzept und Wahrnehmung", in HMD Praxis der Wirtschaftsinformatik (2023) 60: 1124-1142.

There are already many other options that are not listed here and there will be even more in the future.

Lesson 11 - Changing job profiles - The Emsi Burning Glass Study 2022

The utilisation and expansion of human resources and skills is more important in the age of Industry 5.0 than in Industry 4.0 because the focus is shifting from purely technological development to greater integration of people and technology as well as sustainable and value-oriented production. This is creating new areas of activity for companies as well as new forms of collaboration that companies need to adapt to.

The Emsi Burning Glass Study 2022 provides a comprehensive analysis of labour market trends and changing job skills requirements. For the study, over 15 million online job adverts from 2016 to 2021 were analysed to see how the skills required in job profiles have changed over time.

This resulted in a Skill Disruption Index, which looks at 680 occupations and takes into account the 20 most important skills for each occupation. It shows a clear change: Overall, 37% of the most frequently required skills needed for an average job in the American labour market have changed since 2016. The Emsi Burning Glass study assumes that this is a global trend. A fifth of the skills (22%) are completely new requirements. Particularly in certain industries and areas such as finance, design, media, corporate management, human resources and IT, job profiles have changed faster than in other areas.

Here is a list of the 15 professions affected by the biggest change in skills:

Employment |

Skill Disruption Index |

Data Engineer |

100 |

Computer scientist |

95 |

Web developer |

94 |

Validation engineer |

90 |

Network engineer/architect |

88 |

Business Intelligence Architect/Developer |

88 |

Database architect |

88 |

Industrial designer |

87 |

Software developer/engineer |

86 |

Engineer/architect for computer systems |

83 |

Advertising/Promotion Manager |

83 |

Computer programmer |

83 |

Robotics Engineer |

83 |

UI/UX Designer/Developer |

83 |

Developer of mobile applications |

82 |

Table 4: Occupations with the greatest change in skill profile

In these occupations with the highest Skill Disruption Indices, almost 80% of the required top 20 skills are either new or have gained or lost importance. Examples of occupations in this category are: Accounting Manager, Advertising/Promotions Manager, Marketing Assistant, Software Developer/Engineer, Solar Engineer.

In contrast, the following occupations have changed the least:

Employment |

Skill Disruption Index |

Welder/ solderer |

35 |

Caretaker/ cleaner |

35 |

Casino operator |

34 |

Tree climber/trimmer |

34 |

Flushing power |

34 |

Lifeguard |

33 |

Assistant teacher |

33 |

Packaging specialist |

33 |

Labourers/warehouse workers |

33 |

Painter |

32 |

Forklift truck driver/ pallet truck driver |

32 |

Concreter |

31 |

Musician/singer |

27 |

Bus driver |

24 |

mystery shopper |

0 |

Table 5: Occupations with the least change in skill profile.

Many of these jobs require manual skills, such as warehouse workers, packers, caretakers, lorry drivers and dispatchers.

It is important for companies to be aware of the trends in job profiles in order to proactively fill their company with the right employees or to prepare existing employees appropriately for the changing jobs through further training measures.

Lesson 12 - A changed job profile - the example of the marketing specialist

According to the Burning Glass Study from 2022, the requirements for a job in marketing have changed significantly in the last five years. Of the skills required, 20% are said to have been newly added since 2016, while a further 40% have significantly changed in importance. Knowledge in the areas of digital marketing and digital data form the basis for the further development of skills in this function. Interestingly, certain skills that were originally fundamental to the profession have completely lost their importance. According to the study, these include: market research, customer contact, knowledge of the retail industry and marketing communication.

Jobs in marketing are changing, primarily due to the increasing role of technological applications, the shift to data-driven strategies and the emergence of new digital channels. Just think of how well content creation can be taken over by AI, which can generate social media posts, product descriptions or even design elements. AI can also help with SEO optimisation, as AI is able to analyse a large amount of data on the web in a short space of time. AI can also be helpful in the field of predictive analytics to predict product sales or analyse the behaviour of target groups. These are just a few examples of how the traditional marketing function is undergoing a technological transformation.

Source: https://pixabay.com/de/photos/digitales-marketing-rechner-5816304/

Lesson 13 - New resources and expertise for Industry 5.0

The utilisation and expansion of human resources and skills is more important in the age of Industry 5.0 than in Industry 4.0 because the focus is shifting from purely technological development to greater integration of people and technology as well as sustainable and value-oriented production.

Industry 5.0 puts people back at the centre. This stage of development is about how machines and technologies can support human creativity, decision-making and individualisation. To do this, people need specific skills that enable close collaboration between humans and machines. The skills that increasingly need to be developed include

- Creativity and problem solving: people are redesigning the way intelligent machines work together and developing (customised) solutions.

- Flexibility and adaptability: Collaboration with intelligent machines requires the combination of expertise from several areas in order to be able to work fluently with new technologies.

- Ability to learn and curiosity: Working with intelligent machines will constantly present people with new situations, which is why people must develop a willingness to learn throughout their lives.

- Interpersonal and communication skills: Working with sophisticated machines demands communication and leadership skills from people.

In addition, Industry 5.0 presents companies with the responsible task of utilising resources sustainably in order to promote environmental awareness in society. This requires the expansion of sustainable resource strategies, which were often not yet a priority in Industry 4.0.

Source: https://pixabay.com/de/photos/seifenblase-kunst-irisierend-3490959/

Lesson 14 - Future of Jobs Report 2023 - Skills of the future

According to the World Economic Forum's Future of Jobs Report 2023, the following ten skills will be the most important by 2027, based on the survey of 800 companies. Here is a tabular ranking with estimated shares of demand:

Rank |

Core skill |

Share of demand (%) |

1 |

Analytical thinking |

9.1% |

2 |

Creative thinking |

8 % |

3 |

Technological expertise (e.g. AI, big data) |

6.5% |

4 |

Curiosity and lifelong learning |

5.7% |

5 |

Resilience, flexibility and agility |

5.6% |

6 |

Motivation and self-confidence |

5.5% |

7 |

Leadership and social influence |

5.3% |

8 |

Empathy and active listening |

5.1% |

9 |

Attention to detail and reliability |

4.9% |

10 |

Quality assurance and control |

4.7% |

Table 6: adapted from Future of Jobs Report 2023

The table shows the skills that companies consider to be core skills for their employees. The percentages reflect the extent to which these core skills are seen by organisations as fundamental in relation to others. In terms of analytical thinking, for example, this skill is considered a core competency by more companies than any other competency and accounts for an average of 9% of the core competencies reported by companies. As these skills are particularly indicative of the future world of work, training programmes should focus on them.

In addition, skills in the areas of "artificial intelligence" and "data analysis" are expected to grow. Many companies will focus their training programmes on these areas.

Lesson 15 - Industries and skills development - A study by the WEF Future of Jobs Report 2023

The analysis of the World Economic Forum Future of Jobs Report 2023 shows that certain sectors need to invest particularly heavily in the further training and retraining of their employees in order to remain competitive and adaptable to the changes brought about by Industry 5.0. The need for targeted training and further education in these sectors relates primarily to the areas of new technologies, sustainability requirements and new leadership challenges.

Below is an overview of the top 3 industries and the skills they need to prioritise for employee training and development:

- Automotive and aviation industry

Skills:

- Technological capabilities

- Leadership and social interaction

- Environmental and sustainability competences.

As a result of technological change and collaboration with intelligent machines, new skills are required in the area of leadership and social interaction. Almost 40% of companies plan to prioritise these soft skills to better prepare their employees for leadership roles. The transition to electric and self-driving vehicles requires the development of new technological competences. Industry 5.0 is focussed on the environment, which is why sustainable production methods are increasingly in demand in these industries.

- Energy industry, agriculture and green jobs

Skills:

- Sustainability expertise, for example in the area of renewable energies

- Technological expertise

- Problem solving skills.

With the increasing demand for sustainable energy sources and improved environmental awareness, agricultural and energy companies need to invest in developing capabilities in climate change mitigation technologies and renewable energy. Agriculture must adapt to the increased use of technology and high-tech agricultural machinery and the growing demand for sustainable practices and products.

- Education sector

Skills:

- Technological expertise, for example in the area of digital teaching methods

- Creative and analytical thinking

- Lifelong learning.

The education sector is facing an increased need for technological skills to keep pace with the growing demand for digital education and new forms of teaching. Teachers are also expected to be trained more in creative methods to encourage innovative approaches to learning.

The skills that need to be developed in these sectors are also required in other industries. Other sectors will also have to invest in further training in the coming years in order to remain competitive. It is no coincidence that the willingness to engage in lifelong learning is cited as one of the key skills of the employees of the future.

Lesson 16 - Discrepancy between training provision and skills requirements

According to the WEF Future of Jobs Report 2023, companies see skills gaps in the local labour market as the biggest obstacle to industrial transformation. They see investment in training and development in the workplace as the most promising strategy for realising their business goals. It is therefore crucial to develop effective retraining and upskilling strategies over the next five years to optimise business performance.

According to the 2023 report, companies estimate that 41% (2020: 42%) of employees have already completed further training to fill skills gaps. Companies see the priority of further training measures in the years 2023 to 2027 primarily in the areas of analytical thinking (10% of initiatives) and creative thinking (8%). This is an appropriate reflection of the demand for these skills. But this is not always the case. There is a certain discrepancy between the training measures actually implemented and those that companies should implement based on the data. Although some skills, such as analytical and creative thinking, are among the top priorities of training strategies, there are areas such as artificial intelligence (AI), big data and leadership skills that are more strategically emphasised by companies than their current importance to the workforce. The same applies to the areas of leadership and social influence, which are also being promoted more strongly than their current importance would suggest.

In contrast, other areas such as environmental responsibility and design and user experience, which will become strategically more important in the future, are not yet sufficiently represented in training programmes.

Source: https://pixabay.com/de/illustrations/training-bildung-entwicklung-1848687/

Lesson 17 - Training methods

In order to prepare employees for the changing requirements of the labour market and to close skills gaps, various types of training can be considered for different content:

1. on-the-job training: Learning directly on the job is considered one of the most promising strategies to continuously improve employees' skills and achieve business goals. It is often more practical to develop specific skills on the job rather than releasing employees for external training.

2. retraining (reskilling): Many professions are changing dramatically, which is why employees need to be prepared for completely new tasks and technologies. In order to do justice to this, companies rely on retraining. The focus is often on technological skills such as

- Artificial intelligence,

- Big data and

- Cybersecurity.

These skills are increasingly in demand, although they are not yet widespread in the current world of work.

3. further training (upskilling): The aim of further training is to improve existing skills or learn new competences. In the coming years, upskilling will focus on

- Analytical thinking and

- creative thinking

- Networks and cyber security

- Dealing with AI

- Dealing with big data

These skills are fundamental to the increasing importance that the areas of problem solving, innovation and digitalisation will have in the future.

4. interdisciplinary training (cross-functional skills): It will also become more important for companies to develop cross-functional skills in their employees, for example in the areas of design and user experience, environmental responsibility and marketing. This training will help employees to become more versatile and adaptable in an increasingly dynamic working environment.

5. e-learning and online courses: According to the Future of Jobs Report 2023, organisations are increasingly looking to e-learning platforms such as Coursera to align their training strategies with employee learning choices. Online training offers flexible, accessible ways to upskill and is often used to teach technology skills.

In a dynamic labour market, it is probably essential that companies can respond quickly to the changing needs of their employees. Different types of training programmes, which are based on and adapted to learning habits, needs, company capabilities and content, generally offer a good mix to meet the specific needs of companies and their workforce.

Source: https://pixabay.com/de/illustrations/lernen-uhr-ziffernblatt-zeit-415341/

Lesson 18 - Sustainability in Industry 5.0 - Definition of sustainability

One of the many definitions of sustainability can be found on the portal of the Baden-Württemberg State Centre for Political Education: Sustainability or sustainable development means satisfying the needs of the present in such a way that the opportunities of future generations are not restricted. This relates to ecological, economic and social aspects. It is therefore about the responsible use of the finite resources on our planet so that current and future generations worldwide can lead a life worth living - according to their needs. Put simply, we must not live today at the expense of tomorrow! We should not consume more than can be provided again in the future.

Source: Chatgpt

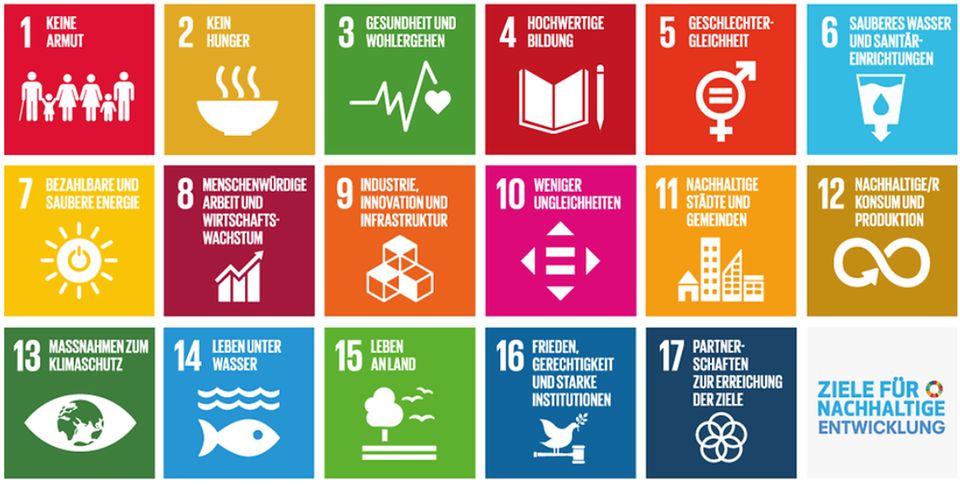

Lesson 19 - Principles and goals of sustainability - Agenda 2030

In 2015, under the auspices of the United Nations, the global community adopted 17 sustainability goals as part of Agenda 2023, which are intended to enable a decent life worldwide and protect the earth's natural resources. They are summarised below.

The goals take into account economic, ecological and social aspects. The 2030 Agenda makes it clear that only joint action by all can bring about change. Politics, business, science, civil society and each and every individual are equally called upon to take responsibility.

Lesson 20 - Importance of sustainability for Industry 5.0

The connection between people and technology is essential in Industry 5.0 in order to promote not only personalised and efficient production, but also sustainable production. Sustainability in the concept of Industry 5.0 means a profound integration of ecological, social and economic goals in industrial production that both protects the environment and puts people at the centre. Compared to Industry 4.0, which focuses on digitalisation, automation and networking, Industry 5.0 goes one step further by strengthening human-machine collaboration while emphasising long-term ecological responsibility.

Here are the main aspects of sustainability in the context of Industry 5.0:

1. ecological sustainability:

Industry 5.0 strives for resource-conserving and environmentally friendly production by using innovative technologies and processes to minimise the ecological footprint. This includes:

- Circular economy: Minimising waste and reducing resource consumption by redesigning and redesigning products so that they can be reused or recycled.

- Energy efficiency: monitoring and optimisation of energy consumption through the use of artificial intelligence (AI) and data analysis.

- Reduction of CO₂ emissions: Use of technologies to minimise CO₂ emissions, whether through the use of clean energy sources, more efficient production processes or smart logistics solutions.

2. social sustainability:

The concept of Industry 5.0 places people at the centre. This means that the role of people in production is upgraded and working conditions are created that are safer and more fulfilling. Examples of this are

- Human-machine collaboration: Close cooperation between machines and humans, with robots taking on repetitive or dangerous tasks while humans concentrate on creative, strategic and value-adding activities.

- Workplace safety and wellbeing: Using automation and smart technologies to improve working conditions, reducing dangerous or physically demanding tasks and giving workers more control over their work.

- Education and training: Lifelong learning takes centre stage so that the workforce can keep pace with technological change. This promotes professional development and personal fulfilment.

3. economic sustainability:

In addition to ecological and social aspects, economic sustainability also plays a role in Industry 5.0. The aim is to ensure long-term economic stability without exploiting resources and the environment. This includes

- Increasing efficiency through smart technologies: Using AI, the Internet of Things (IoT) and digital twins to optimise production processes, save resources and make production more flexible.

- Personalised products: Production of customised products according to specific customer requirements through flexible and digital production systems, leading to a reduction in overproduction and waste of resources.

- Long-term value creation: focussing on sustainable business models that benefit the company as well as society and the environment.

In the concept of Industry 5.0, technological innovations are therefore not only used to increase efficiency, but also to protect the environment and improve people's well-being. Industry 5.0 is a holistic transformation of industry in which ecological and social responsibility go hand in hand with economic profitability. Industry 5.0 creates a human-centred, environmentally friendly and sustainable future in which technological advances are used for the common good.

Source: https://pixabay.com/de/illustrations/technik-technologie-baum-gr%C3%BCn-6742648/

Lesson 21 - Sustainability through intelligent production - the Siemens Amberg electronics factory as an example

The Siemens Amberg electronics factory can be seen as an example of the sustainable implementation of Industry 5.0. Siemens combines smart technologies with sustainable production methods and at the same time puts people at the centre:

1. use of artificial intelligence (AI) and data analysis

- Use of artificial intelligence (AI) and big data to monitor and optimise energy consumption in real time. This allows the production process to be organised more efficiently by identifying and reducing energy waste.

- Monitoring of the production process using smart sensors. Energy consumption is thus precisely controlled, e.g. by optimising machine running times and minimising downtimes.

2. circular economy and material efficiency

- Recycling and reusing a large proportion of raw materials and materials. Integration of circular economy principles into production in order to minimise waste and use resources more efficiently. Materials are designed in such a way that they can be reused at the end of their life cycle.

- Longevity and repair of products to minimise the need for frequent replacement.

3. human-machine collaboration

- Use of collaborative robots (cobots) to work together with humans. These robots take on heavy and repetitive tasks, while human workers can concentrate on creative and strategic activities. This not only improves occupational safety, but also increases job satisfaction and efficiency.

- Controlling and monitoring the robots and machines is simple and intuitive, allowing employees to easily intervene in the processes and adapt the systems as required.

4. renewable energies and CO₂-neutral production

- Switch to renewable energies to reduce CO₂ emissions and use solar energy and wind power to cover the factory's energy requirements. The aim is to achieve CO₂-neutral production.

- Integration of smart grids and energy management systems to optimise the adaptation of energy consumption to the availability of renewable energies.

5. digital twins for sustainable production

- Use of "digital twins" to simulate and optimise production processes in a virtual environment. This allows resources to be conserved by recognising and eliminating errors and inefficiencies as early as the planning phase.

- Digital simulation of various scenarios to determine the most environmentally friendly option, whether in terms of material consumption, energy utilisation or product design.

The example of Siemens' Amberg electronics factory clearly shows how Industry 5.0 can have an impact on environmental and social responsibility through the use of the latest technologies and production principles as well as co-operation between man and machine.

https://www.siemens.com/de/de/unternehmen/standorte/fertigungs-und-entwicklungsstandort-amberg.html

Lesson 22 - In-depth study of Industry 5.0 and sustainability - Siemens factory video

Watch this video about Siemens Amberg Elektronikfabrik on U tube! Do you recognise the principles of Industry 5.0?

Lesson 23 - Industry 5.0 - advantages for people

Industry 5.0 offers the advantage that technology works for people. This significantly improves working conditions. The following overview shows what has changed compared to Industry 4.0:

Working conditions |

Industry 4.0 |

Industry 5.0 |

Job security |

Human workers often perform (supervised) hazardous or repetitive tasks. |

Robots take over dangerous and monotonous tasks. This increases the safety of people. |

Workplace ergonomics |

Automation improves efficiency, but human ergonomics are often neglected. |

Greater consideration of workplace ergonomics. For example, cobots take on physical loads. |

Diversity of work processes |

Simple, repetitive tasks are reduced by automation, but not completely eliminated. |

Robots and AI take over monotonous tasks so that people can concentrate on creative and strategic work. |

Workload |

Increased pressure due to higher efficiency requirements. |

Machines take over repetitive and physically demanding tasks, which means less stress for people. |

Work-life balance |

Increased efficiency requirements can lead to longer working hours or greater intensity. |

Better work-life balance through physical relief and more creative and varied tasks. |

Job satisfaction |

Automation reduces the human role in production, which often leads to frustration or uncertainty. |

Increased motivation and satisfaction as people take on more responsibility and creative roles and are supported by technology. |

Not only will Industry 5.0 increase efficiency, but working conditions for people will also improve thanks to greater safety, more ergonomics and a greater focus on people's needs, thus increasing job satisfaction.

Lesson 24 - Criticism of the term Industry 5.0

Although the term Industry 5.0 is used and endorsed by the EU and many economic institutions, dissenting voices have also recently emerged. In Germany, for example, the Industry 4.0 Research Advisory Council and the Industry 4.0 Platform have criticised the term. The points of criticism are as follows:

Unnecessity of the term: Human-centricity and the integration of technologies such as AI, which are emphasised as the main feature of Industry 5.0, are also central components of Industry 4.0. The criticism is that Industry 5.0 does not offer any new content, but merely gives existing concepts a different name.

Confusion and uncertainty: Small and medium-sized companies in particular are still in the implementation phase of Industry 4.0, and the introduction of the term Industry 5.0 could unsettle them. One point of criticism is that the introduction of the new term could hinder progress in the implementation of Industry 4.0.

Implementation of Industry 4.0 not yet complete: The proposal of a new Industry 5.0 concept could be premature, as companies are still in the implementation phase of Industry 4.0.

Despite the difficulties in defining the content of the concepts, the advantage of the term Industry 5.0 is that it clearly focuses on certain aspects such as sustainability, focussing on people and human-machine collaboration for the benefit of people.

Lesson 25 - Challenges and hurdles in the introduction of Industry 5.0

The introduction of Industry 5.0 presents companies with a wide range of challenges that extend to technological as well as human and organisational aspects.

Are costs and investment requirements exploding? The transition to Industry 5.0 requires massive investment in new technologies such as artificial intelligence, robotics and intelligent automation. For small and medium-sized enterprises (SMEs) in particular, these investment costs could represent a significant barrier. On the other hand, Industry 5.0 could offer them a competitive advantage because the success of a company depends more on the skills of its employees than on location and infrastructure.

What about data security and cyber security? With the increasing networking of machines and systems, the risk of cyber attacks is also growing. Creating secure, robust systems that are protected against cyber threats is a key challenge.

Are employees on board with the changes? The introduction of new technologies is often met with resistance, especially from employees who fear that they could be replaced by machines. Company management must also be prepared to adapt to the changes and integrate them into their business models.

Overall, however, the advantages of Industry 5.0 will outweigh the disadvantages

Source: https://pixabay.com/de/illustrations/schl%C3%BCsselw%C3%B6rter-ver%C3%A4nderung-fische-2488210/

Lesson 26 - Ethical considerations

With the introduction of Industry 5.0 and the increasing use of intelligent machines, ethical aspects are coming to the fore that were previously not present to the same extent. They affect numerous areas such as labour law, data protection, social justice and copyright and present companies with the task of adopting clear positions in this regard. Some questions are listed below as food for thought:

Who is responsible for errors? Industry 5.0 increasingly relies on collaboration between humans and machines. This raises the question of who is responsible for errors or wrong decisions when AI-based systems make decisions. The person who programmes the machine? Or the company that uses it? Or - quite hypothetically - the intelligent machine itself? The clarification of the question of responsibility must be addressed in terms of liability and moral responsibility.

Will some workers become redundant? Although Industry 5.0 puts people at the centre of things, progressive automation could make certain jobs redundant. An ethical company invests in the training of its workforce to prepare them for working with AI in good time and to ensure that the transition to a more automated industry is socially just.

Are intelligent machines monitoring their human companions? With the increased use of sensors, data analysis and AI to optimise production processes, there is a risk of increased surveillance of employees. This "digital surveillance" could restrict the privacy of employees and lead to ethical concerns regarding freedom in the workplace. Employee education and data protection should be a new priority for companies.

In the transition to the Industry 5.0 concept, the endeavour to establish clear ethical guidelines, transparency and a sense of responsibility is not just the responsibility of companies. Clarification of these aspects will only succeed through co-operation between politics, business and society.

Source: https://pixabay.com/de/illustrations/richtig-falsch-karikatur-ethik-7472524/

Lesson 27 - Websites on ethics and AI

Find out more about ethical issues in connection with the use of artificial intelligence on these pages

Artificial Intelligence Act (AI Act) https://artificialintelligenceact.eu/

The pages of the Montreal AI Ethics Institute (MAIEI), which contain many articles on the topics of ethics and AI, can also be helpful https://montrealethics.ai/

Lesson 28 - Risks associated with the use of AI in Industry 5.0

Collaboration with intelligent machines blurs the boundaries between human labour and creativity and machine performance. As a result, the use of generative artificial intelligence in particular is associated with risks. Some of these are listed here:

1. dissemination of critical content: AI can inadvertently or intentionally generate content that is inappropriate, offensive or misleading. This could happen, for example, through automatically generated emails that contain inappropriate wording and are sent without being checked.

2. copyright infringements: AI models utilise large amounts of data, the sources of which are often unclear. This could lead to copyright infringements or plagiarism with legal consequences for companies.

3. data protection: Generative AI models could contain personal data. Companies must ensure that this information is protected and not misused.

4. unintentional disclosure of sensitive information: Working with easily accessible AI systems could inadvertently expose sensitive company data or personal information about the AI itself to the wider public, which could damage trust in companies and their brands.

5. reinforcement of existing prejudices: AI systems learn from large amounts of data. If this data contains prejudices, the AI will adopt and reproduce these prejudices. For example, an AI could preferentially select men for technical professions when viewing applications, as women were/are traditionally underrepresented in these professions.

6 Incorrect information: AI systems can provide false information if the data they have been fed is incorrect or inaccurate.

7. lack of causality: AI systems work with probabilities. Therefore, when questioning an AI, the answer will, with a certain probability, be the one that the AI considers most appropriate. An answer generated in this way does not necessarily correspond to the causal reason.

These risks require careful governance, legal safeguards and an ethically sound use of AI in companies.

Source: https://pixabay.com/de/illustrations/cyber-gehirn-computer-gehirn-7662721/

Lesson 29 - Industry 5.0?

Take a look at the AI-generated image. Does it match the information you received in this module on Industry 5.0? If yes, why? If no, why? Take a minute to reflect!

Source: Chatgpt

Lesson 30 - Summary

Industry 5.0 represents a significant step forward in industrial development by putting people back at the centre of industrial processes. In contrast to Industry 4.0, where the focus was on automation and efficiency, Industry 5.0 concentrates on combining the skills and creativity of people with modern technologies.

Industry 5.0 focuses not only on technological innovation, but also on sustainable and people-centred production. It emphasises the need to promote economic growth in harmony with ecological goals. The change in job profiles is central to Industry 5.0. New technologies are changing the skills requirements, as the Emsi Burning Glass study shows. Particularly in areas such as IT, engineering and design, the skills required have changed significantly. Creativity, problem-solving, flexibility and lifelong learning will be indispensable in the working world of the future.

This makes further training and retraining all the more important. Skills gaps resulting from the technological transformation need to be closed. The importance of continuous professional development is also reinforced by the focus on sustainability, where there is also a need for training.

Human-machine collaboration reduces physical strain, promotes job security and allows employees to focus on more fulfilling tasks. Taking greater account of the supporting activities of machines such as collaborative robots leads to a better work-life balance.

However, there are also voices that criticise the concept of Industry 5.0. Some experts are of the opinion that the term is superfluous, as many of the principles described are already contained in Industry 4.0. Nevertheless, Industry 5.0 offers a clear focus on sustainability and humanity, which has been lacking in previous industrial development.

Overall, Industry 5.0 offers the opportunity not only to increase efficiency through the intelligent use of technology, but also to assume ecological and social responsibility. Industry 5.0 is therefore a holistic transformation in which technological innovations are harmonised with the well-being of people and the environment.

Good practice 1 - Bosch - Example of Electromobility

Source: https://pixabay.com/de/photos/f%C3%A4higkeiten-3371153/

To counter demographic change and the labour shortage, Bosch is focusing strongly on education, training and the use of smart technologies. In 2022, Bosch organised over 30,000 training seminars worldwide with more than 520,000 participants. A particular focus is on teaching technology skills in areas such as electromobility and software engineering. In 2023, the company planned to train around 50% more associates than in the previous year. Bosch also offers external interested parties numerous training opportunities via in-house academies and training centres. Over 100 programmes on digitalisation and connected manufacturing are available to other companies, including Bosch Connected Industry and Bosch Rexroth. These initiatives emphasise Bosch's commitment to actively contributing to further training in the context of new technologies and helping to shape the future of industry.

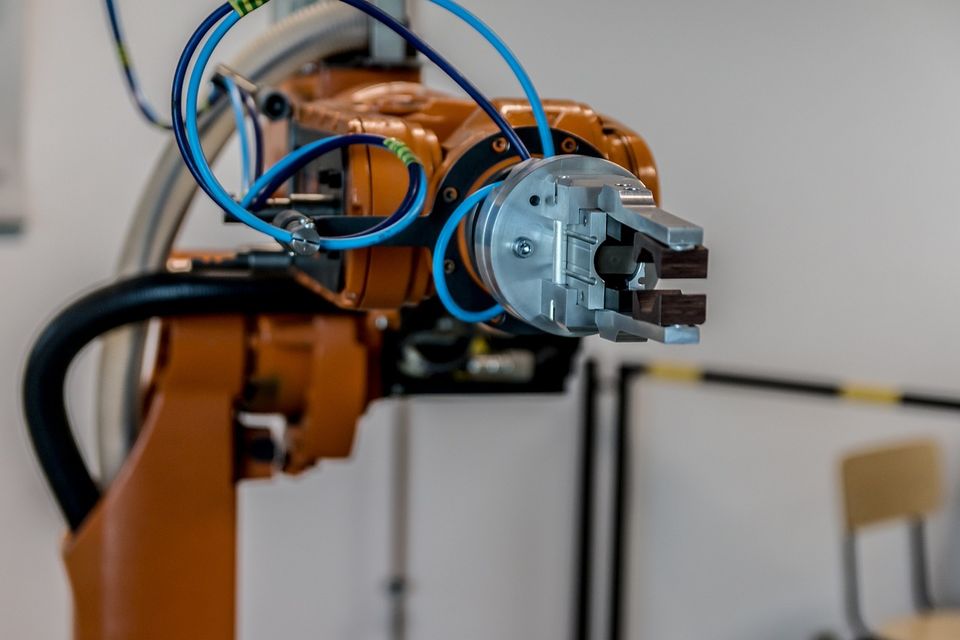

Good practice 2 - Festo - Example of Collaborative Robotics

Source: https://pixabay.com/de/photos/roboter-arm-technologie-roboterarm-2791671/

Festo is an internationally operating company in the field of automation and technological innovation. It is a good example of Industry 5.0 because it pursues collaborative robotics projects in which robots and humans work together to make processes more efficient and safer. The "Bionic Learning Network" develops robotic systems that imitate natural movements and optimise interaction with humans. Festo also manufactures products that cater to individual customer requirements, always focussing on the sustainability of processes and results. With Festo Didactic, a division of Festo, the company has also firmly anchored employee training and development in its business model, helping people to adapt to the changing world of work and develop throughout their lives.

https://www.festo.com/de/de/e/ueber-festo-id_3847/

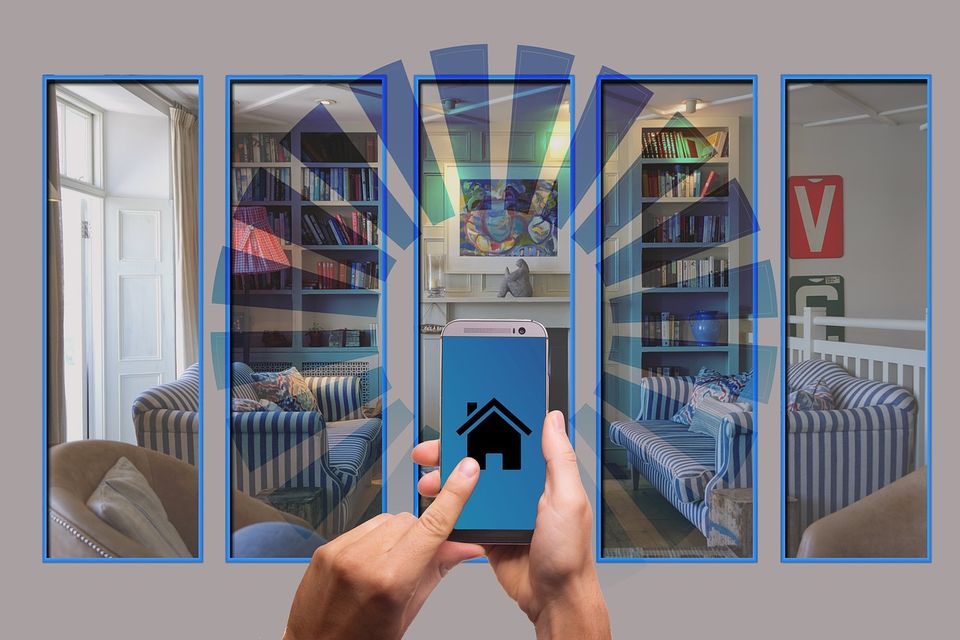

Good practice 3 - Schneider Electric – Example of IoT

Source: https://pixabay.com/de/photos/smart-home-haus-technik-multimedia-3653454/

One example of the successful implementation of the principles of Industry 5.0 is Schneider Electric. It is a globally active company in the fields of energy and automation technology. Among other things, it develops and produces switchgear, circuit breakers, transformers and energy monitoring systems. It can be considered an example of the implementation of the principles of Industry 5.0 because, among other things, the company is concerned with making energy more efficient and sustainable, for example with smart home solutions, intelligent systems for energy optimisation and control of lighting systems in residential buildings, thermostats and security systems.

Good practice 4 - Asea Brown Boveri - Example of Collaborative Robotics

Source: https://pixabay.com/de/photos/verbindung-hand-mensch-roboter-3308188/

The Swiss company ABB (Asea Brown Boveri) is an example of the implementation of the principles of Industry 5.0 in the field of robotics. The globally operating group was formed in 1988 from the merger of the Swedish company ASEA and the Swiss company BBC.

ABB develops collaborative robots. One well-known example is the YuMi robot, which works flexibly and easily programmable with humans in industrial manufacturing processes. The company also focuses on the digitalisation of industry. The ABB Ability™ platform is an IoT platform that enables companies to monitor, analyse and optimise their production processes, thereby achieving greater flexibility and efficiency. The platform integrates technologies such as artificial intelligence (AI) and big data that support human decision-making and enable more customised production.